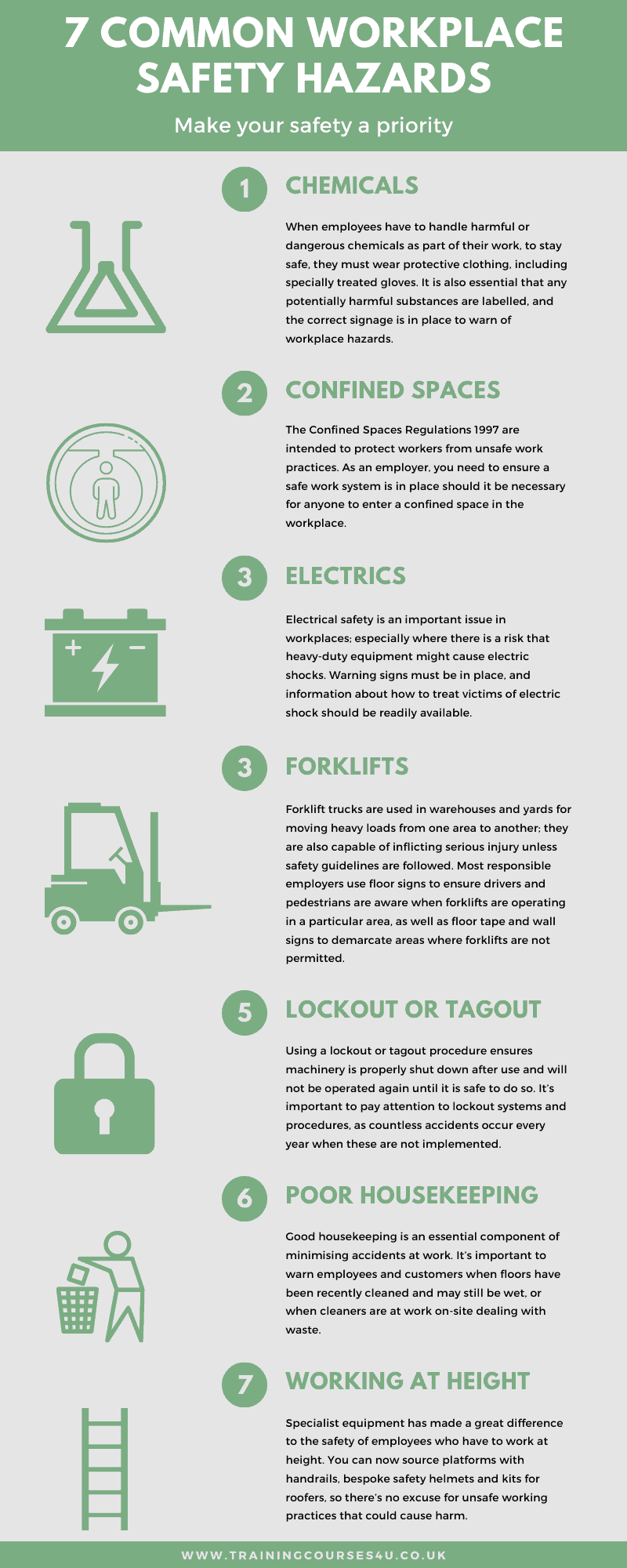

7 Common Workplace Safety Hazards

Workplace safety hazards are everywhere. They lurk in every corner of the workplace. From the office to the factory floor, there are plenty of ways to get injured at work.

If you want to stay safe at work, then you need to be aware of these common workplace safety hazards. By being aware of these dangers, you can reduce your risk of injury and keep yourself and others around you safe.

Chemicals

One of the most dangerous types of workplace injuries is chemical exposure. Chemicals come from a variety of sources including cleaning products, paints, solvents, glues, fertilizers, pesticides, herbicides, and more. If you’re exposed to chemicals on a regular basis, it could cause serious health problems like cancer or even death.

When employees have to handle harmful or dangerous chemicals as part of their work, to stay safe, they must wear protective clothing, including specially treated gloves. It is also essential that any potentially harmful substances are labelled, and the correct signage is in place to warn of workplace hazards.

Confined Spaces

A confined space is any area that has limited access for people. These areas may have low ceilings, tight corners, narrow passageways, or other features that make them difficult to navigate safely. Confined spaces often contain hazardous materials such as gases, liquids, dusts, fumes, and mixtures of all three. In addition, they also pose risks to workers who enter them because they lack adequate ventilation.

The Confined Spaces Regulations 1997 are intended to protect workers from unsafe work practices. As an employer, you need to ensure a safe work system is in place should it be necessary for anyone to enter a confined space in the workplace.

Electrics

Electricity poses many threats to employees working near electrical equipment. Electrical shocks, electrocution, burns, and falls are just some of the potential consequences of getting too close to electricity. It is estimated that there are about 1 million electric shock-related deaths occur each year worldwide.

Electrical safety is an important issue in workplaces; especially where there is a risk that heavy-duty equipment might cause electric shocks. Warning signs must be in place, and information about how to treat victims of electric shock should be readily available.

Forklifts

The forklift is one of the deadliest machines used in construction and in manufacturing facilities today. It carries heavy loads over long distances with ease. However, this machine comes with its own set of hazards. Forklifts can tip over easily if not properly maintained. This type of accident can result in severe injuries or even death.

Forklift trucks are used in construction and warehouses and yards for moving heavy loads from one area to another; they are also capable of inflicting serious injury unless safety guidelines are followed. Most responsible employers use floor signs to ensure drivers and pedestrians are aware when forklifts are operating in a particular area, as well as floor tape and wall signs to demarcate areas where forklifts are not permitted.

Lockout or Tagout

This refers to an employee locking themselves out of their workspace while performing maintenance or repairs. Lockouts happen when someone forgets to turn off power before starting work. Tagouts refer to situations where an employer locks down a piece of machinery so no one else can use it until it's fixed.

Using a lockout or tagout procedure ensures machinery is properly shut down after use and will not be operated again until it is safe to do so. It’s important to pay attention to lockout systems and procedures, as countless accidents occur every year when these are not implemented.

Poor Housekeeping

Housekeeping includes everything from sweeping floors to mopping up spills. While it might seem simple enough, poor housekeeping can lead to accidents. For example, a worker walking through a wet room could slip and fall into a puddle of water. Or, an employee using a brush to clean a window sill could accidentally knock something onto another person below. Poor housekeeping can also increase the likelihood of slips and trips.

Good housekeeping is an essential component of minimising accidents at work. It’s important to warn employees and customers when floors have been recently cleaned and may still be wet, or when cleaners are at work on-site dealing with waste.

Working at Height

Many jobs require workers to climb ladders, scaffolds, stairs, roofs, etc., which puts them at increased risk of falling. Falls account for nearly half of occupational fatalities among construction workers. Working at heights can also expose workers to harmful substances like asbestos, silica sand, and concrete dust.

Specialist equipment has made a great difference to the safety of employees who have to work at height. You can now source platforms with handrails, bespoke safety helmets and kits for roofers, so there’s no excuse for unsafe working practices that could cause harm.

This infographic quickly breaks down the 7 most common workplace safety hazards.